Replacement fuel caps

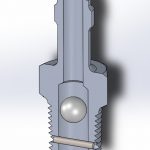

Aluminium cap with spin-up nut and knurled lock nut. These are a direct replacement for the original “thermos flask” pressure caps. They work by expanding a standard BS324 O ring. Replacement O rings cost less than $2. Mass = 125 grams or 4.4 oz Price: A$80

Aluminium cap with spin-up nut and knurled lock nut. These are a direct replacement for the original “thermos flask” pressure caps. They work by expanding a standard BS324 O ring. Replacement O rings cost less than $2. Mass = 125 grams or 4.4 oz Price: A$80

Nylon/aluminium fuel cap – the same design as above but the upper part of the cap is machined from P6 nylon for reduced weight. Mass = 85 grams or 3 oz Nylon has good fuel resistance, but is in any case not in contact with fuel. This is the type I have fitted to my own Sonex. Price: A$75

Nylon/aluminium fuel cap – the same design as above but the upper part of the cap is machined from P6 nylon for reduced weight. Mass = 85 grams or 3 oz Nylon has good fuel resistance, but is in any case not in contact with fuel. This is the type I have fitted to my own Sonex. Price: A$75

Note that the lock nut can be eliminated if a locking device is fitted to the fuel door. Here’s the non-locking fuel cap and a simple lock fitted to the fuel door. When the door is closed the attached channel (supplied with the cap) prevents rotation of the wing nut.

These caps are based on a design by Rodger Connolly who has generously supplied the drawings to other Sonex builders.

On current exchange rates (20/5/16) these fuel caps are cheaper than the original replacement part, look better than the original cap and work better than the original cap, but it’s a tough call.

Fuel vent check valve

I like to think that the products I sell are useful, but I think that this one is almost essential. It will save you fuel (and money) and it might just save your life.

The danger

The fuel vent on my Sonex is just a short forward-facing tube. An advantage of this type of vent on a tail-dragger is that the fuel tank can be completely filled. A big danger is that in the event of the aircraft becoming inverted in an accident, much of the fuel can run out the vent. I also noticed that with the fuel tank more than 3/4 full, during any low-g manoeuvre, or even a moderately steep descent, fuel would come out the vent. I think this will occur whether the vent comes out the top or the bottom, but if you have the tank venting at the bottom you can’t see it happening.

How it works

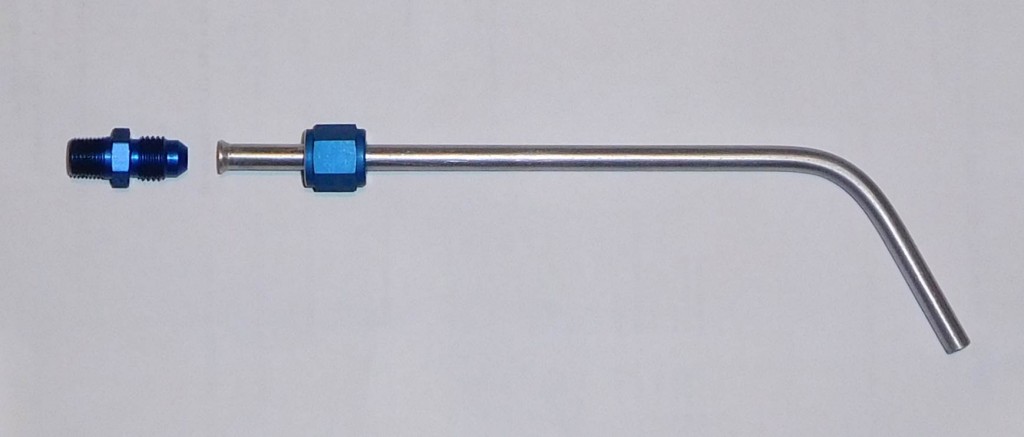

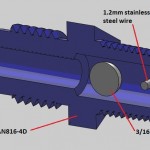

The valve is made from an AN816-4D fitting . The end is drilled out to 6 mm and a 3/16″ ball inserted and retained by a pin through a cross-hole. The ball is a 3/16″ PTFE (Teflon) sphere which has high resistance to avgas and mogas. The Teflon ball is denser than fuel so will still block the vent if the aircraft is inverted, but is light enough so that fuel pressure will keep it against the seat during low-g .

I have tried a variety of manoeuvres, bunts and steep to gentle descents with a nearly full tank and observed no leakage.

Fuel tank vent assembly incorporating check valve

Note: Some “tweaking” of the tube to clear the fuel door is required. Price: A$40 assembly

Note: Some “tweaking” of the tube to clear the fuel door is required. Price: A$40 assembly

Check valve – 1/8 NPT to 1/4 hose barb

For those preferring to vent their fuel tank under the aircraft, these are machined from Al 6061-T6 hex bar to fit a 1/4″ vent hose.

Price: A$25

Check valve – 1/8 NPT to 1/4 hose 90° bend

Price A$40

Check valve with 90° bend – AN822-4D

Also suitable for venting the fuel tank under the aircraft

1/8″ NPT to 1/4″ OD tube. Price A$40

Price: A$20

Price: A$20