The correct name for this tool is “DSTO Reamer Guide”, because it was built for DSTO, the Defence Science Technology Organization, but among the working group, it is universally known as the Klingon.

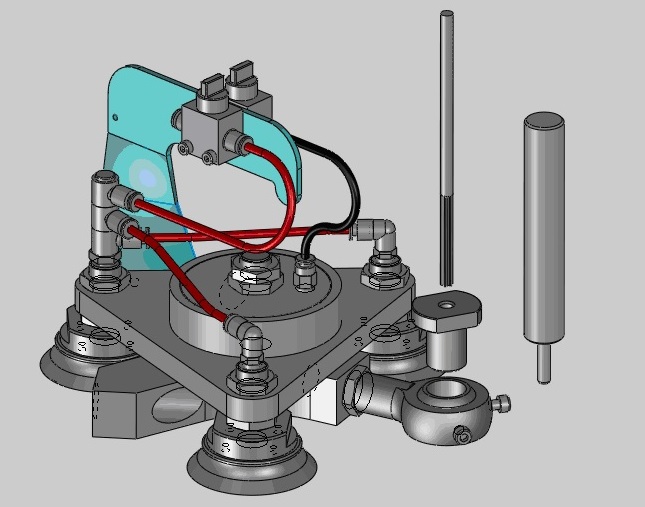

Here’s the story. Many of the fastener holes in modern aircraft need to be accurately machined to a high standard of finish. The holes for fasteners such as “Hi-lok” and “Hi-tigue” are specified as ±0.001”. This can normally be achieved by enlarging an existing hole using a piloted reamer, that is a reamer with a non-cutting lead which guides the reamer into the hole, but the accuracy of the final hole depends to a large extent on the fit of the pilot in the starting hole. With a poor fitting pilot, it is difficult to maintain the correct angle with a hand drill, so that holes can become oval, or “belled” near the surfaces. A poorly reamed hole can wreck a part which is usually worth many thousands of dollars. Here’s the gizmo I came up with:

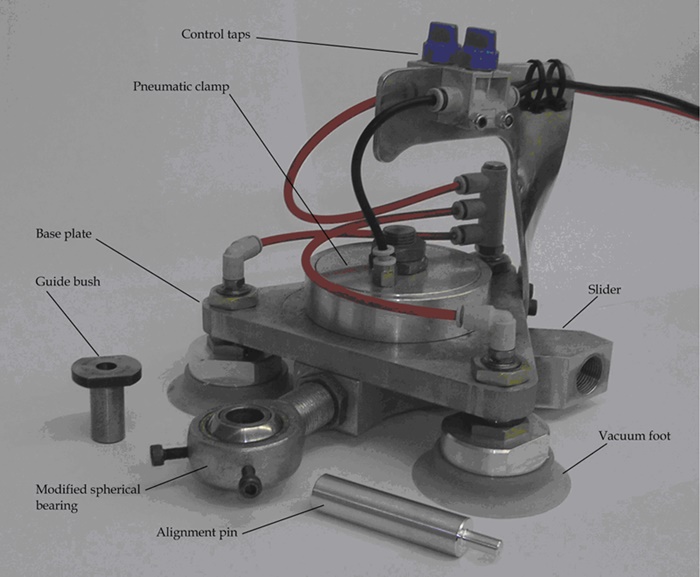

The tool consists of a base plate fitted with three modified commercial vacuum pads. A sliding block under the base plate is free to rotate and move in fore-aft directions until air pressure is applied to a pneumatic clamp. Attached to the block is a spherical bearing which can be locked by two clamp screws. The idea is that when it’s clamped in place, a guide bush is perfectly aligned with the hole to be reamed. We used it on the wings of a test aircraft with carbide reamers and HSS bushes made by “Ultracut” from Hamilton, Victoria to consistently produce holes within ±0.00025″. And here it is in the metal. These are hardly a high volume item, but we have made 15 or 20 of them and they are used by a major international company for doing wing upgrades.

And here it is in the metal. These are hardly a high volume item, but we have made 15 or 20 of them and they are used by a major international company for doing wing upgrades.

The above photograph appears in the DST Group 2016 calendar.

Since the above story was written, the tool has been granted an international patent. I’d love to tell you what the patent covers but I don’t speak legalese. Here’s the next step:

Defence Innovation Licensed to South Australian Company _ Department of Defence Ministers

I don’t know how long this link will last but here’s a link to some info on the commercially made tool: Precise Global

And here is the commercial tool itself: Got to admit it looks prettier than the ones I made.

Got to admit it looks prettier than the ones I made.